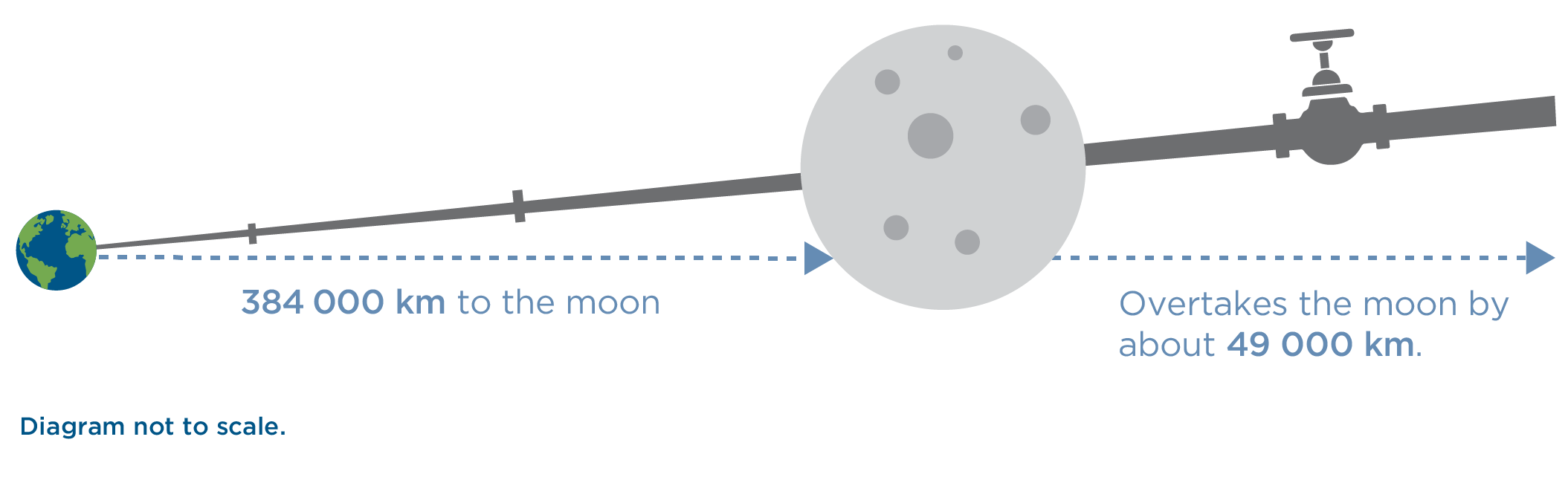

Every day in Alberta, a complex network of pipelines operates right under our feet, moving oil and gas to markets at home and beyond. In fact, oil and gas pipelines stretch more than 433 000 kilometres across the province. It’s our job to regulate these pipelines and ensure that they’re safe.

Which pipelines are we responsible for?

We only regulate pipelines within Alberta’s borders, with the exception of utility pipelines, which are regulated by the Alberta Utilities Commission. Oil and gas pipelines that cross provincial or international borders are regulated by the Canadian Energy Regulator.

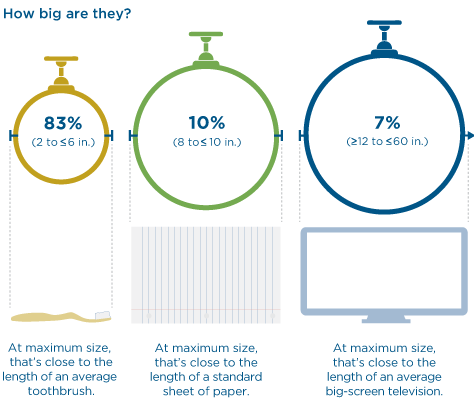

Most pipelines that we’re responsible for are smaller lines that connect individual wells to processing facilities, which then connect to larger-diameter lines. We also provide inspection and incident and emergency response support for 12 000 kilometres of utility pipelines.

Types of Pipelines

Pipelines transport various liquids and gases. In 2018,

- 57 per cent of Alberta's total pipeline inventory carried natural gas.

- 16 per cent carried oil well effluent.

- 6 per cent carried sour natural gas (natural gas with hydrogen sulphide concentrations greater than 1 per cent).

- 5 per cent carried fuel gas.

- 5 per cent carried salt water, and

- 11 per cent carried other substances, such as fresh water and low vapour pressure products.

How We Regulate Pipelines

Our work starts before a pipeline is built and continues after it’s no longer in use. From the time an application is submitted for a pipeline through to the pipeline’s construction, operation, and closure, our requirements help ensure that it is designed, operated, and closed safely, and that the land is returned to its natural state.

Rules and Requirements

Throughout the life of a pipeline, all companies must comply with the following rules, regulations, and requirements:

- Pipeline Act,

- Pipeline Rules,

- Directive 077: Pipelines – Requirements and Reference Tools, and

- Canadian Standards Association (CSA) Z662-19: Oil and Gas Pipeline Systems.

Companies must also identify, manage, monitor, and address any potential hazards associated with individual pipelines. To do this, we require companies to develop comprehensive integrity management programs, and safety and loss management systems.

Over the years, Alberta’s pipeline requirements have been examined against those of other regulators around the world to ensure that we follow best practices. Find out how we’ve improved our requirements to reduce pipeline incidents.

How We Inspect Pipelines

We inspect pipeline operations regularly to ensure that companies are meeting our requirements and are monitoring for potential risks. Our inspections consider the risks of individual pipelines and look at pipeline fluid characteristics, location, line size, failure history, and the company’s compliance history.

Pipelines with greater risks—such as those that transport oil effluent, salt water, and sour gas; are located near water bodies; or belong to a company with poor compliance history—receive greater scrutiny.

Compliance and Enforcement

If we find that a company isn’t meeting our requirements, or if there is a risk to the public or the environment, we can immediately suspend the pipeline until the problems are corrected. Other compliance and enforcement tools that we might use include warning letters, administrative penalties, orders, and prosecution.

We share all of our compliance and enforcement decisions on our Compliance Dashboard.

When an Incident or Emergency Occurs

All pipeline incidents in Alberta must be reported to us, including when a pipeline is hit but does not leak. Pipeline incidents can be caused by

- corrosion due to poor maintenance or construction practices;

- equipment failure;

- material and welding defects;

- natural events such as ground movement or flooding; or

- human interference, such as when a pipeline is hit by heavy equipment during ground disturbance or through vandalism.

Roles and Responsibilities

Companies are responsible for all aspects of incident response—from having a detailed emergency response plan to guide incident response through to remediating and reclaiming a site after an incident. We assist the company in its response, and our staff are on hand to respond to energy-related incidents 24 hours a day, 7 days a week.

Learn more about how we respond to incidents and investigate the cause.

Sharing Information

Every year, we publish a Pipeline Performance Report that highlights companies that are performing well, as well as those that need to make improvements. We work with companies to improve their performance—whether that means conducting inspections and audits more often, educating them on pipeline integrity, or taking enforcement action—to prevent future incidents.

The report is part of our industry performance program, which measures, evaluates, and reports on the energy development activities that we regulate.

Forms for Industry

Safety and Loss Management System (SLMS) Self-Assessment and Declaration Form [PDF]